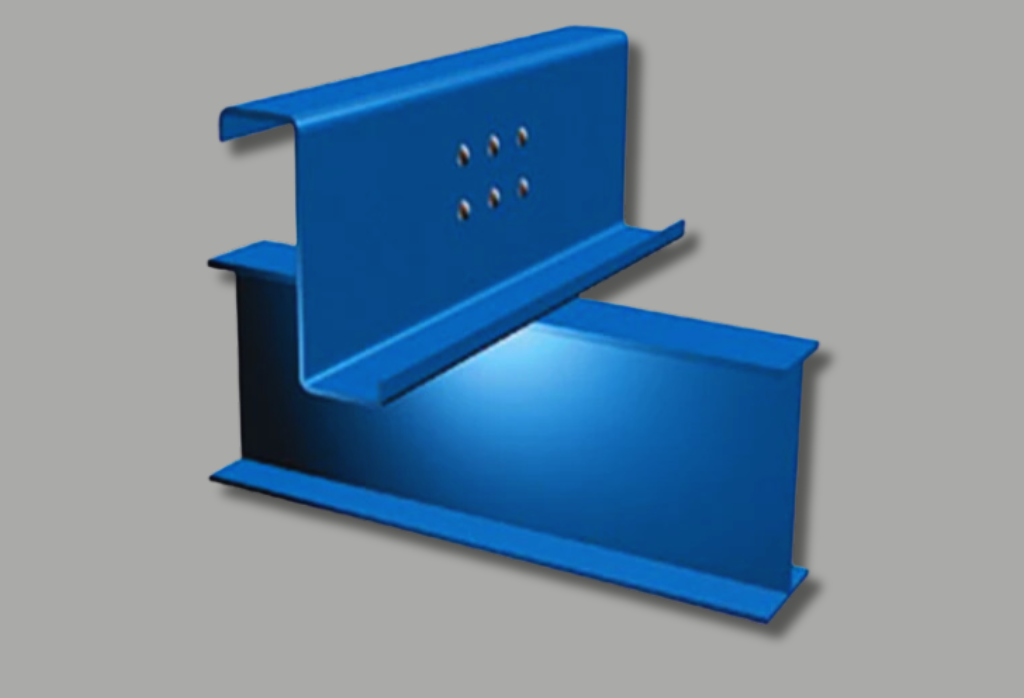

Z & C purlins offer durable structural support for roofs and walls.

BSSM INFRA purlins, girts, and eave struts are secondary structural members used to support wall and roof panels. BSSM INFRA purlins are utilized on the roof, girts on the walls, and eave struts at the intersection of side walls and roofs. BSSM INFRA purlins, girts, and eave struts are designed in accordance with the American Iron and Steel Institute (AISI) and the cold-formed design manual. BSSM INFRA sections can be used over single spans, unlapped continuous, and lapped continuous spans in multi-bay buildings. BSSM INFRA Z&C purlins are available in two standard finishes: Red Oxide and Galvanized.

| Purlin DEPTH | Thickness | Mass | ZED PURLIN | CEE PURLIN | ||

|---|---|---|---|---|---|---|

| D | T | (Kg/M) | F | L | F | L |

| 160 | 2.00 | 4.82 | 60 | 20 | 60 | 20 |

| 200 | 2.00 | 5.44 | 60 | 20 | 60 | 20 |