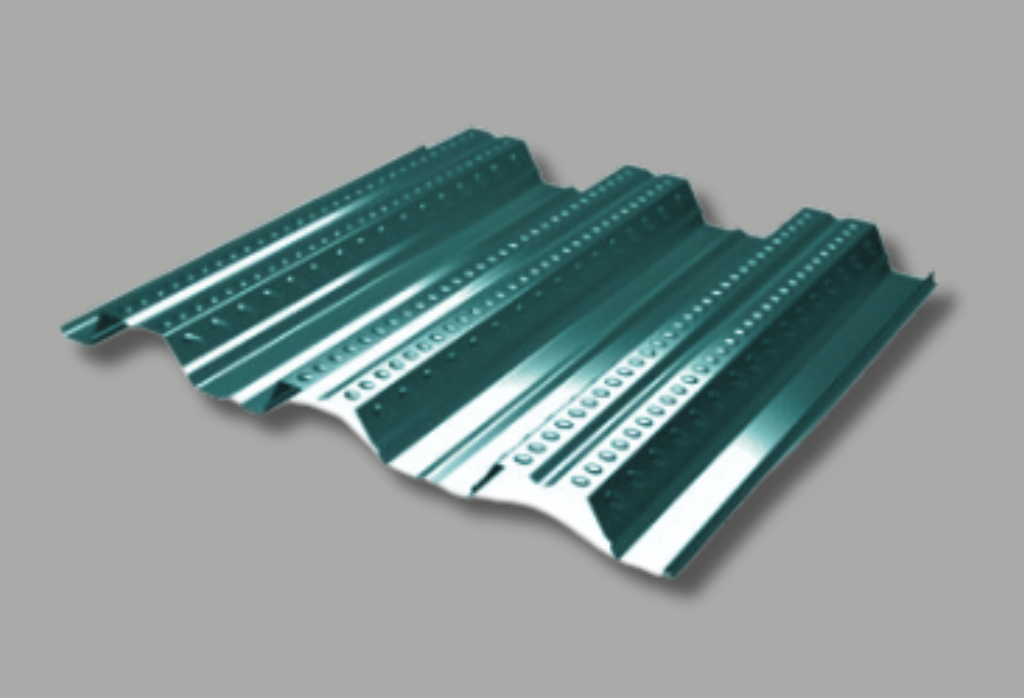

Floor deck sheets deliver strong support and efficient construction.

The floor consists of a profiled sheet onto which a layer of concrete is poured. The sheet is bonded to the concrete through mouldings that prevent horizontal slipping and vertical detachment. During the initial hardening phase (Stage 1), the sheet solely supports the weight of the concrete, personnel, and equipment. Once the concrete has hardened (Stage 2), the sheet and concrete form a unified bond, exhibiting the characteristics of traditional reinforced concrete, with the sheet acting as metal reinforcement. Appropriate crop ends must be provided to absorb negative moments. This solution is offered by BSSM INFRA.

Reduced Concrete Usage: Tensile steel for composite slab construction minimizes slab thickness and reduces the dead weight of buildings, offering a more sustainable solution and lowering costs.

The technical department at BSSM INFRA provides comprehensive advisory services on the design of composite flooring. For any queries not covered by this literature, please feel free to contact us.

| Panel Thickness | Design Thickness | Profile Weight | Area of Steel | Height of neutral axis | Moment pof Lnertia | Sagging | Hogging |

|---|---|---|---|---|---|---|---|

| mm | mm | kg.m2 | cm2 | mm | cm4 | KN.m/m | KN.m/m |

| 0.8 | 0.77 | 7.66 | 9.76 | 37.80 | 100.90 | 4.004 | 3.983 |

| 1.0 | 0.97 | 9.57 | 12.19 | 38.12 | 126.10 | 4.993 | 4.962 |

| 1.2 | 1.17 | 11.97 | 15.25 | 38.28 | 157.70 | 6.230 | 6.179 |

| Panel Thickness | Profile Weight | Sectional Area | Concrete slab depth above profile | |||

|---|---|---|---|---|---|---|

| mm | kg/m2 | cm2 | 100mm | 150mm | 200mm | 250mm |

| 0.80 | 7.66 | 9.46 | 2.90 | 2.50 | 2.30 | 2.000 |

| 1.00 | 9.57 | 12.19 | 3.30 | 2.80 | 2.50 | 2.300 |

| 1.20 | 11.97 | 15.25 | 3.70 | 3.20 | 2.80 | 2.600 |

Lightweight and requiring no additional support, this system significantly decreases concrete usage and slab thickness.